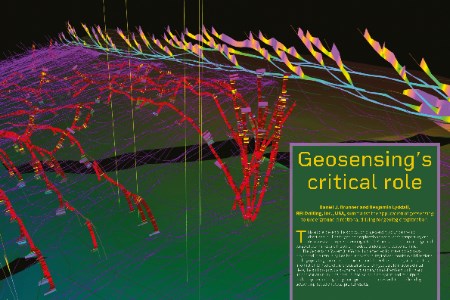

Geosensing's Critical Role

Published by Jess Watts,

Editorial Assistant

World Coal,

This article presents the application of geosensing to underground directional drilling for geologic exploration from a user’s perspective, and discusses two projects operating in North America – one in an underground longwall coal mine, and the other in a deep underground evaporite mine.

The Geosensing System (the Yabby) implemented for these projects was developed in Australia by Coalbed Innovations, Pty Ltd and monitors all directional drilling operating parameters on the drill and the wellhead. The system uses this information to interpret the characteristics of any geologic formations drilled. The following provides a summary of underground directional drilling and its applications to mining, describes the Geosensing System and its outputs, and compares current geologic interpretation practices with those offered by geosensing, based on actual project results.

Underground directional drilling

Underground directional drilling is performed with high-thrust electric-over-hydraulic powered drills. Fluid is pumped down the drill rods (3.7 – 5.7 l/sec. (60 – 90 gal./min.)) at high pressure using triplex pumps to rotate a helical rotor in an elastomer-lined stator, which rotates a full-face bit downhole. A bend behind the bit, typically one to two degrees, is oriented opposite to the desired drilling direction, and thrust is applied to advance the bit. Directional drilling is used to steer boreholes within coal seams and adjacent strata in advance of mining for purposes such as degasification, geologic exploration, old works verification, water drainage/transfer, stress relief, and instrumentation installation. This technology is not limited to coal mines and is also applied in evaporite, hard rock, and oil mines, as well as civil tunneling projects. Directionally drilled boreholes over 1800 m (6000 ft) long have been placed accurately in rock from underground operations.

The orientation of the bend is derived using an LWD/MWD instrument installed behind the bit. The DDMS LWD/MWD system developed by Drilling Products, Inc. sends data uphole through insulated centralised conductors inside the rod string to a drill-mounted computer. The downhole LWD/MWD instrument uses magnetometers and accelerometers to derive the relative position of the sensors in the instrument to the drill collar (up/down and left/right, relative to the collar). Nearest to the bit is a focused gamma sensor, which is oriented to collect upward and downward (0° and 180°) measurements at each survey point. These surveys are taken every 3 – 6 m (10 – 20 ft) as drill rods are added. The LWD/MWD system plots the current bit position in plan and profile view, including focused gamma as a function of orientation, and the onboard computer can accept drilling plans so that directional drilling can be performed on a drill-to-plan basis. This data is simultaneously relayed to the Geosensing System.

This is a preview of an article that was originally published in Issue 1 of World Coal 2025.

Subscribe to World Coal for free to read this article in full and many more here.

Read the article online at: https://www.worldcoal.com/coal/06082025/geosensings-critical-role/

You might also like

Thiess secures six-year contract to expand operations at Mount Pleasant Operation

Thiess has secured a new six-year contract with MACH Energy at the Mount Pleasant Operation in the Hunter Valley, New South Wales, Australia.