Plowing Ahead

Published by Jody Dodgson,

Editorial Assistant

World Coal,

Underground coal mining continues to impose increasing demands on the machinery used in terms of safety, efficiency, and load-handling capacity, thereby driving technological innovation. HBT plow systems and face conveyors are well-established in the market. Conveyors equipped with Controlled Start Transmission (CST) technology – offering installed power of up to 3x 1800 kW – allow for both soft and abrupt starts using motor stall torque. Plow systems with drive power ratings of 1600 kW can achieve production rates of up to 20 000 tpd.

Lately, variable frequency drive (VFD) technology has been introduced and has demonstrated key advantages over conventional systems: variable speeds, precise torque control using standard motors, regenerative braking, and improved overload protection. Additionally, separating motors and inverters enables more flexible and compact system layouts. This article compares conventional and variable-speed drive technologies using simulation models verified with field data. Simulations allow the evaluation of new control concepts and their effects on system behaviour, especially under dynamic conditions such as abrupt starts, blockages, or overloads. These insights provide a basis for system optimisation.

Introduction

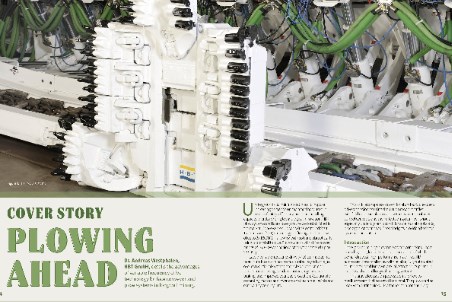

Underground mining presents extreme conditions – heat, humidity, dust, limited space, and noise – all of which demand robust, high-performance machines. HBT addresses these challenges with reliable, fully automated solutions tailored for raw material extraction. Its portfolio includes advanced longwall mining systems. This article focuses on plow systems for low to medium seam thicknesses of hard coal.

The plow – a steel body with cutting picks – is attached to a continuously circulating chain driven from both ends of the face. Guided along a chain scraper conveyor, the plow cuts coal from the seam in both directions. Typically, asynchronous squirrel-cage motors combined with HBT UEL overload gearboxes are used for the plow system, while CST gearboxes are used on the conveyors. In recent years, the adoption of VFD technology has gained traction due to its excellent control characteristics.

This is a preview of an article that was originally published in Issue 2 of World Coal 2025.

Subscribe to World Coal for free to read this article in full and many more here.

Read the article online at: https://www.worldcoal.com/special-reports/15102025/plowing-ahead/

You might also like

Boosting profits and sustainability: The power of cyclones in Canadian coal mining

Niel Lourens, Vice President for Cyclones & Spirals at Multotec, discusses how advanced cyclone systems are helping Canadian coal mines cut waste and boost recovery.